How To Fix Miata Short Nose Crank Issue

What Virtually Those Crankshafts?

Past Lance Schall

lkschall@earthnet.net

WHAT IS THIS I HEAR ABOUT BROKEN CRANKSHAFTS?

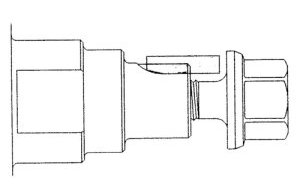

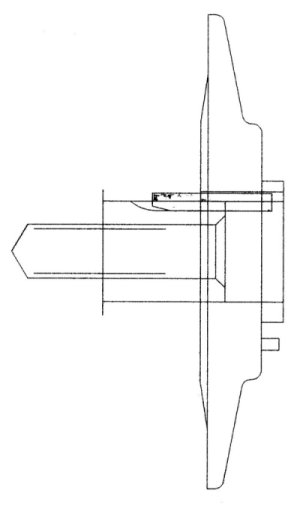

There have been reports of broken crankshafts past almost ane% of Miata owners. The trouble is confined to 1990 and early 1991 cars. Difficulties are related to the crankshaft nose, keyway, cam drive sprocket, or pulley bolt (Figure i). Failures are often precipitated by the removal of the pulley bolt and cam sprocket to facilitate front crankshaft seal replacement. In the past, we recommended renewing the front seal during timing belt service as preventative maintenance. At present, information technology would seem prudent to leave the pulley bolt undisturbed provided the seal is non leaking. Luckily, information technology is not necessary to remove the bolt and sprocket in the course of regular timing belt service in 1990 and early 1991 cars.

| Brusque nose - | Big nose - |

Figure 1 - This is a cutaway diagram of the original crankshaft and cam sprocket assembly. Annotation the incomplete engagement of the key in the short crankshaft slot. Appointment area of the fundamental in the crankshaft slot is 0.045 in2.

SOUNDS Fairly CRITICAL

It is. This malfunction renders the car inoperative. Replacement of the crankshaft requires removal of the engine. The crankshaft costs about $450. Miscellaneous parts and labor must button the repair into the neighborhood of $1500.

THE CRANKSHAFT MUST BE REPLACED?

Your choices are to replace the crankshaft, substitute a dainty used engine from a relieve yard, or install a new mill short block. Generally the least expensive alternative depends on each private situation. Machine shop repair of the crankshaft is not unheard of. I suppose if you constitute a really skilful shop...if you are unemployed...or living in a third world country.... Well, I don't want to hear about information technology.

WHY DOES It BREAK?

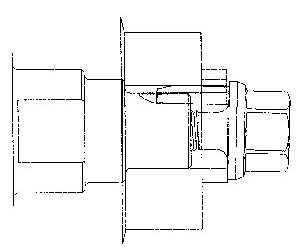

Typically, the central wears the keyway slot in the crankshaft nose. Worn keyways are not repairable. In other cases, the caster bolt will fail to stay tightly screwed to the front of the crankshaft. Insufficient tightening torque upon assembly is an obvious cause. Some other less intuitive failure is excess torque can stretch the bolt which causes looseness. In some of the incidents, inserting the fundamental into the keyway upside-down resulted in an interference fit (Figure 2). This improper assembly tin stress the commodities, causing the caput to break off. The misalignment also causes subversive imbalance. The imbalance can break the crankshaft. I should bespeak out that some cardinal and slot combinations are such that the cardinal will fit in the slot either way without interference. It is also possible that five-belt tension and the forces necessary to bulldoze the accessories may cause cyclical loading that leads to a fatigue failure of the crankshaft olfactory organ itself. We have closely examined perhaps a half dozen crankshafts. It is often not possible to decide what part of the assembly failed first.

Figure 2 - With the chamfered end of the square key incorrectly positioned, the key is forced out of sprocket slot and the bolt shank may be bent. This assembly volition not survive long.

ARE There SYMPTOMS?

In some of these scenarios, difficulties may not exist immediately detectable. Normally a worn keyway will consequence in a poor running engine as the crankshaft loses its position relative to the camshafts. It is hard to diagnose considering the relative positions of the timing mark on the pulley and crank position sensor on the back of the intake cam do not change. That is, the timing lite reports ignition timing is OK. Some owners experienced poor operation as the slipping sprocket immune relative crankshaft and camshaft timing to wander. If the crankshaft nose breaks off, this is easy for a mechanic to diagnose. The car will not run and the mechanic finds the pulley assembly laying on the lower splash shield. In all examples, repair is the same; replace the crankshaft.

I Tin can HAVE A Trouble WITHOUT NOTICING?

Yeah, it is possible to seem fine today and have a broken crankshaft tomorrow. It can happen at any fourth dimension, regardless of mileage or whether you take had the threescore,000 mile timing chugalug change. That said, it appears that failures are more likely after the pulley bolt has been carelessly replaced and ordinarily within a few hundred miles. Although sudden and catastrophic failure is possible, many victims detect degraded engine operation or a noticeable pulley wobble.

IS THE Pattern OF THE CRANKSHAFT POOR?

Certainly, it is fair to say that the design is non tolerant of associates errors. Put the central in wrong or go bolt torque incorrect, and information technology is all over. It is also clear that the original short olfactory organ crankshaft is not a particularly efficient use of bachelor knowledge on the role of Mazda. I sympathize the Mazda 323 had the same problem. On the other paw, if the crankshaft was stiff enough to never pause, the auto would not counterbalance 2200 lbs. Keep in mind that a vast majority of 1990 Miatas are running many miles past their timing chugalug change and to over 100,000 miles without any problem. The 1991 1/2 and later crankshaft is certainly better than the early function. It is piece of cake to expand this concept to include the idea that the 1990 to 1991 1/2 crankshaft blueprint is, indeed, poor. At this point, however, I tin not extrapolate to convince myself that Mazda should recall all early Miatas and install new crankshafts.

Information technology might be fair for an owner and Mazda to share a pro rated price of an up-grade between zilch and 100,000 miles. Of course, if we broke within one thousand miles of a dealer timing chugalug alter, he should option upwards the tab. Still, what is fair and what the factory volition practise may be ii different things. No auto manufacturer, in my experience, has e'er been able to see by the finish of the warranty. Your, time, coin, and sense of justice volition have to exist your guide on what you lot desire to practise. The Federal Government'southward regulatory attention is primarily safe and emissions bug.

MAZDA SUGGESTS THAT INCOMPETENT REPAIR IS THE ROOT CAUSE.

No, information technology is one cause.

Clumsy repair techniques or inadequate tools is ever a recipe for disaster. The factory claims the mid-yr change in 1991 was to "improve serviceability". This is partially true. The new crankshaft is more robust. Only when cars assembled in Hiroshima or repaired by trained Mazda dealers have crankshaft failures, it is clear that blame should non be laid entirely at the feet of the nearest shade tree mechanic.

Nosotros have traced only two failures to the reversed central. In i of these cases, the central was reversed on the other side of the ocean. In the last 1990 motorcar I worked on, the cardinal would fit cleanly into the keyway backwards. In two other failures, we are sure the primal was inserted correctly. In several incidences, the key position could non be determined.

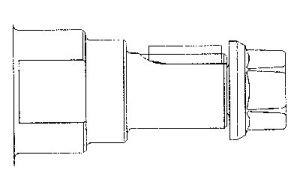

Tin can I Check MY MIATA TODAY?

Yep and no. If your Miata is a 1992 or newer, forget this article. You take nothing to worry nigh. If you have a 1991 with VIN 209447 or more, you're safe. If you'd similar, verify the stronger crankshaft and larger commodities are fitted by measuring the bolt shoulder diameter to exist 1.455 inches. If your Miata is a 1990 or 1991 with VIN 209446 or less, you have a crankshaft with a smaller diameter nose. (Note: co-ordinate to Mazda, the European spec MX-5 breakpoint is at 127442.) The pulley bolt shoulder diameter is 1.128 inches. There is an intermediate fix in the form of a longer nosed crankshaft with the same minor diameter (Figure 3). Unfortunately, we tin not predict whether you have a long nose crankshaft or earlier brusk nose crankshaft. The Loftier Route as been unable to verify whether the long nose creepo was fitted to whatsoever cars at the factory or if it is only a service office. If you order a new 1990 crankshaft from the dealer, yous will automatically get a long olfactory organ version. There is no reliable 5 minute technique to check the condition of your keyway. Verification of these parts requires partial disassembly and examination of the components.

Figure 3 - A quick fix was provided with a longer olfactory organ on the crankshaft. The key is supported along its entire length. Appointment area of the key is almost exactly doubled at 0.087 in2 . The longer olfactory organ besides prevents the key from rotating out of its slot. If information technology is inserted upside-downward, it may beetle beyond the face of the sprocket further. Hopefully, this makes an error more noticeable before the bolt is tightened.

And then I HAVE THE SMALL SHOULDER DIAMETER Commodities

Well, there you have it, the pocket-size bolt. You have two choices. You can ignore the situation completely. Just drive the car. It will probably never requite you whatever trouble. Do y'all listen walking home too much? Your other option is to continue your investigation. Accept your mechanic remove the pulley bolt. No other disassembly is required at this point, just he must not employ an air wrench. Not even for loosening! Detect the exposed tip of the crankshaft. If it is most even with the face of the pulley, yous have the long olfactory organ crankshaft. If the tip of the crankshaft is closer to 1/two inch back in in that location, you lot have the dreaded short nose part. Withdraw the key with needle nose pliers. Make annotation of the chamfered corner, it should be on the back of the fundamental and face toward the crankshaft. The fundamental should non be bent, deformed, or mooshed.

Reassemble using a new cardinal and new bolt. Clean all parts scrupulously including the threads in the crankshaft end. Put the whole affair back together. Yous should be able to push the key home with i finger. All the way in, the primal end is below the surface of the pulley face up. If you can not go information technology in, it is dirty, upside-down, the caster and crank keyways are not lined upwardly (they should not have moved), or the crankshaft keyway is damaged. Use Loctite on the bolt threads and torque to 80 to 87 foot pounds. This is not a minimum torque! It is not a torque proffer, simply rather a specification. Become the best torque wrench yous tin can buy, borrow, or rent. Set up information technology to 83.5 foot pounds. No, I am not joking! Pray your fault is less than 4%. If your mechanic does not seem sufficiently concerned regarding the correct torque, leave. Go to a competent shop. Menstruation.

WHAT ARE THE DEFINITE Problem SIGNS?

To exercise a complete check, nosotros want to go 1 pace by the verification of the fundamental and the replacement of the commodities that I merely described. Speed shops sell over-the-counter dye penetrant inspection kits. This will give you a smashing idea of the condition of your crankshaft nose. To use this examination you will need to remove the camshaft drive sprocket. This will take several hours. On the up-side, if the results are favorable, you have avoided an engine removal. If yous are very risk agin, the key is mangled, or the crankshaft keyway is damaged, you volition want to replace the crankshaft. Of course, the other reason to supersede the crankshaft is if its end is already broken off or the bolt head breaks off when the mechanic tries to loosen it.

I Take BEEN READING THE MIATA MAILING LIST ON THE INTERNET. At that place SEEMS TO BE SOME CONFUSION Almost THE PROPER PULLEY Bolt TORQUE. YOU But SAID 80 - 87 FOOT POUNDS. THE MIATA Magazine HAD 120 Pes POUNDS IN THE 1996 TECH ISSUE. WHAT GIVES?

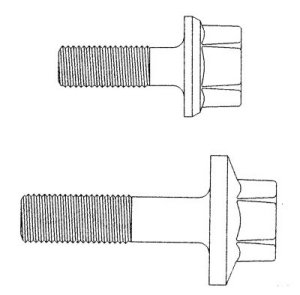

I am dislocated as to why anyone should be confused. Of form, I have a shop manual for every year Miata (two for 1990). I also take four crankshafts on my desk. It's all perfectly clear to me. In 1990, the right torque is 80 - 87 foot pounds. For 1992 and later, the larger crankshaft uses 116 - 123 foot pounds. In 1991, the manual lists both torques in different places. It does not explain why this is and then. Merely now you lot know, VIN 209446 or less and your torque is 80 - 87. VIN 209447 or more is tightened to 116 - 123 human foot pounds. The 120 human foot pound bolt is considerably larger than the 85 foot pound bolt (Effigy 4).

Figure 4 - Upper; Original bolt length is 2.1 inches and shank diameter is 0.428 inches. Rockwell hardness is 36 on a C calibration. Lower; Larger commodities is ii.ix inches long for re-designed crankshaft. Diameter is increased to 0.507 inches. The bore doesn't seem that much larger but it does represent a 40% larger cross section. The hardness of the large commodities is 22 Rc.

IF THE CRANKSHAFT Design IS LAME, WHY REPLACE IT WITH A NEW LAME PART?

Remember yous are probably replacing a brusk nose crankshaft with a long olfactory organ crankshaft. Nosotros have not been able to confirm whatsoever failures of a 1990 long olfactory organ crankshaft. Information technology appears that the quick set, slightly improved, crankshaft has eliminated unexpected field failures. [ If yous discover a broken long nose crankshaft, I want to meet it! For non-members, I volition pay postage from anywhere in the country. ed. ]

IS In that location A REALLY Splendid FIX?

We are adequately sure the long nose crankshaft is reliable. Nevertheless, if you accept more money than yous know what to do with, your Miata can aid you. Yes, the 1991 ane/2 to 1993 crankshaft can exist retrofitted to an early Miata. The crankshaft, pulley commodities, cam sprocket, front seal, pulley, spacer, and oil pump must be replaced as a set. I am not sure about the front cover. At to the lowest degree nosotros know the engine block was not changed for the unabridged life of the Miata 1.6 liter. Realize that the dealer's references volition not completely document this conversion. It is easy enough to practise, but you lot have to play detective with the parts book. Understandably, Mazda did non provide the dealers with details for putting a 1992 crankshaft in a 1990 machine. If any Peak To Peak Miata Order members want to do this conversion, your newsletter editor would welcome the opportunity to be a technical consultant. That is, if necessary, y'all can watch me while I do the work! Past the way, an unabridged engine from a 1992 or 1993 will direct bolt into a 1990 Miata. This is a squeamish style to become the stronger crankshaft (Effigy 5). Keep this in mind if you become with the engine replacement plan.

Figure 5 - Re-designed crankshaft with increased nose diameters. Shown next to original design for comparison. Note the addition of a "pulley boss".

ARE THERE PRECAUTIONS I CAN Take WITH MY MIGHT BE BAD CRANKSHAFT?

If you desire to use the promise-for-the-best-if-I-don't-want-to-touch-information technology method of machine maintenance, here are some unproblematic guidelines:

Be very item about belt tension for the accessory belts and the timing belt. Judging belt tension past the poke-with-finger method is a piddling questionable. Consider buying a chugalug tension checker.

If you lot are due for a timing belt change and the front seal is non leaking, change the timing belt just don't bear on the pulley bolt. The timing belt can exist replaced with out removing the cam drive sprocket from the crankshaft olfactory organ.

It is easy to use the bolt to turn the engine in order to install the new timing belt. Don't do this. Instead, put the automobile in fifth gear and roll it to position the crankshaft. Do not put a wrench on the bolt unless you intend to remove it!

If you really feel similar yous want to do something that might exist effective, supercede the commodities with a new i.

Addendum - August 2001

FORWORD

As the writer of the article that appeared first in the Meridian To Elevation Miata Lodge newsletter, The Loftier Road, and so in the Miata Mag in 1996, it falls to me to provide this update.

Somewhen all 1990 and early on 1991 crankshafts volition fail. Most crankshafts will terminal the life of the original block. The idea that they all fail might have become a not-upshot. But now, those crankshafts are eleven or 12 years old. Second or tertiary owners may be thinking of re-building the engine and returning the short nose crankshaft to service. This effect will exist with the states for a long time.

A SUMMARY OF Three DIFFERENT CRANKSHAFTS

There are iii crankshafts for ane.6 liter engines. Some people mention "short" and "long" when they actually mean "brusque" and "big". Watch for this when you search athenaeum. The crankshafts are the short nose, long nose, and large nose (Figures 1, 3, and 5 respectively). The brusque olfactory organ is fitted on early cars, the long olfactory organ is available primarily as a service part for those cars before the VIN cut in 1991. The long nose crankshaft is directly compatible with a short nose engine with no additional parts swapping required. The short olfactory organ and long nose use the aforementioned caster bolt and torque. Afterward the VIN cut, the big olfactory organ crankshaft is fitted with a bigger bolt. The nose of this crankshaft is larger diameter so a unlike engine front embrace/oil pump is needed. The new oil pump has a bigger hole through the georotor to fit over the larger crankshaft. The big nose bolt has a larger threaded diameter, large shoulder diameter, and higher tightening torque. All of the bolts have 21mm heads.

Too the short nose crankshaft uses the lower timing belt cog as a structural member, that is the cog is bolted to the crankshaft, the accessory pulleys (one v-belt and i serpentine) are bolted to the cog. The timing chugalug cog, in addition to its timing belt rotational duties, must support the rotational and bending forces of the accessory belts. After the introduction of the big nose crankshaft, the timing belt cog has only one job, to rotate the timing belt. Mazda introduced an additional part they call a "pulley boss" (Effigy 5). The pulley boss is a sturdy cast hub that forms a mounting flange on the front of the crankshaft. Information technology is bolted to the crankshaft. The timing belt cog is bolted to the back of the boss and the accessory pulleys are bolted to the front of the boss.

In 1994, the 1.8 liter engine, has two serpentine accessory belts instead of the ane five-belt and one serpentine.

THE PROTRUDING Cardinal IS Non THE SMOKING GUN

I suggest that improper assembly, reversing the primal, is ane failure fashion. Although there is a effigy in this article (Effigy ii) showing a reversed key, the text points out that in that location are several other ways to cause the chain of events leading to failure. It is my fault for writing the article in a way that inappropriately emphasizes the reversed key outcome. I have e'er believed this failure style to be relatively rare.

There are, as has been pointed out in my article and by others, examples of keys that fit in backwards and crankshaft bolts that break without being disturbed. Dealers may be delighted to grasp the straw of clumsy apprentice repair as a root cause. However, in my opinion, the dealers are more effected and annoyed at Mazda's endeavour to foist this problem off on them. In other words, information technology is clumsy dealer technicians that cause the problem! What we meet is the upshot of the lack of whatsoever honest and intelligent advice whatsoever between Mazda and their dealer network. The problem is a Mazda DESIGN issue.

REGULAR REPLACEMENT OF THE BOLT RECOMMENDED

The failure starts at the Commodities. It is undertorqued, overtorqued (stretching and yielding it), or the bolt creeps (stretches or fatigues) over time loosening the connectedness. An overtorqued bolt can not but stretch but crusade the crankshaft threaded end inside diameter to expand. So even a fresh bolt may not retain it'southward torque. In any example as the commodities loosens the key, keyway, and timing cog have a beating. Only the crankshaft shoulder and timing cog tin can take the loads of functioning. When the bolt becomes loose, the load shifts from the crankshaft shoulder to the other parts which rapidly self destruct.

Yes, most of the mistake lies with the weak blueprint that asks too much of that bolt. For this reason, the solution is Non to leave the commodities untouched. That commodities is condign older and older everyday. Every fourth dimension you start the engine, the hazard for failure increases. The bolt should be on a regular replacement schedule. I would recommend annually.

The commodities can be removed and inspected, the key tin can exist slid out (sometimes) and examined without whatsoever other disassembly of the engine. I have a special socket I shortened with a grinder so I can remove the caster bolt without removing the front end anti-roll bar. If you ever find the bolt has non retained its torque, ferrous pulverisation on the bolt or central, or the key rusted or smooshed, these are signs that the system is starting to neglect. Sometimes a wobble can be seen when the engine is running. A wasted crankshaft keyway may, however, still rotate without runout. The static tension in the timing chugalug and accessory belts usually prevents a human hand from wobbling the lower pulley with the engine off. The only mode to get a read on the crankshaft condition is to have the system apart.

If everything is in gild, clean up the crankshaft and bolt shoulder seating surface with brake cleaning spray. Toothbrush the inside of the crankshaft threaded pigsty. Utilise Loctite thread locker or sleeve retainer to a new commodities. Install NEW bolt and cardinal. Torque to 87 pes pounds.

THERE IS A LOCTITE REPAIR

Recognizing that many people can't afford to supersede their engine or crankshaft, I will mention that there are successful repairs involving shims, new keys, welding and the like. Probably the best repair is a Loctite ready that has been developed with the direct aid of Loctite engineers.

How To Fix Miata Short Nose Crank Issue,

Source: https://www.miata.net/garage/crankshaft.html

Posted by: harisowayll.blogspot.com

0 Response to "How To Fix Miata Short Nose Crank Issue"

Post a Comment